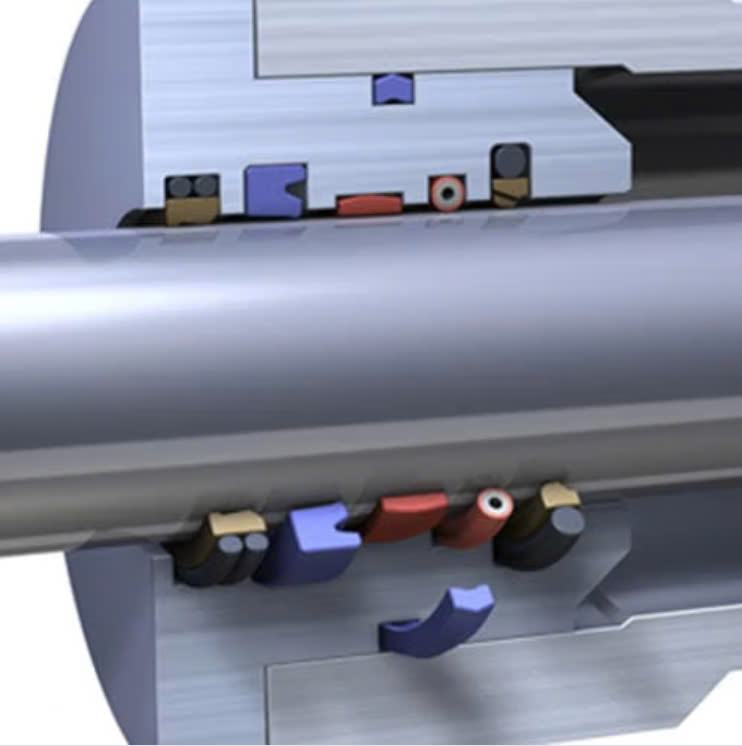

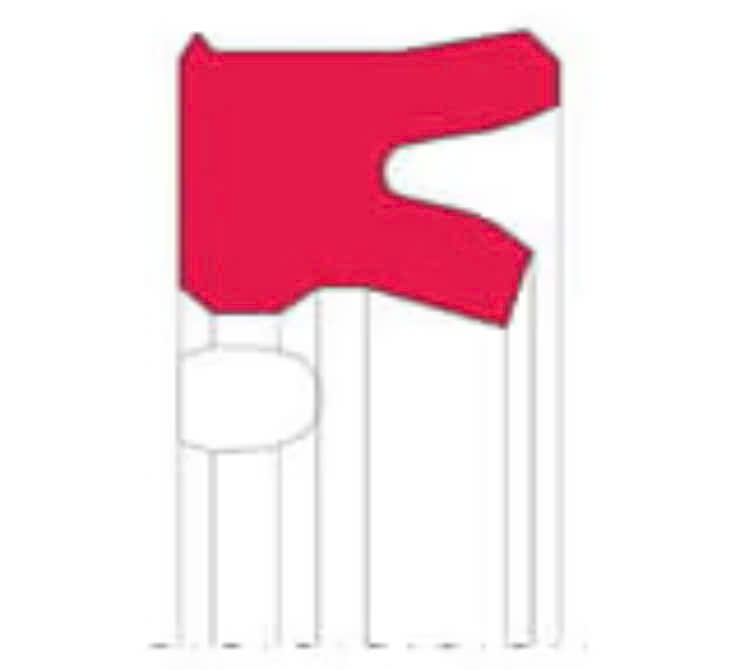

Hydraulic Cylinder Rod Seals & Pneumatic Rod Seals

Rod Seals From Freudenberg Sealing Technologies Perform Multiple Tasks

Rod Seals are primarily used in pneumatic and hydraulic cylinders and have the task of sealing the incoming and outgoing cylinder rod. The goal is to prevent the escape of the pressurized operating medium from the cylinder. At the same time, it must be protected against external contaminants. Freudenberg Sealing Technologies offers the right Rod Seal for every kind of cylinder and application.