Contents

John King offer a series of welded steel chains specifically designed for high impact and abrasing resistance as encountered in timber decks and high duty timber applications. The chain includes fully heat treated chain parts with the addition of induction hardened barrels and rivets. Chains are primarily riveted construction with extra large formed rivet head to ensure maximum integrity.

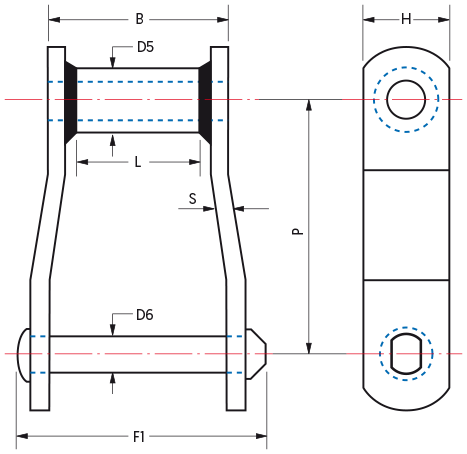

| Chain Number | Pitch (P) (inches) |

Bushings | Rivets | Over-All Pin & Cotter (F1) (inches) |

Between Sidebars (L) (inches) |

Length of Bearing (B) (inches) |

Sidebars | Breaking Load (lbs) |

Average Weight (lbs/ft) |

||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Outside Diameter (D5) (inches) |

Diameter (D6) (inches) |

Thickness (S) (inches) |

Height (H) (inches) |

||||||||

| WH78XHD | 2.636 | 1.00 | 0.56 | 3.38 | 1.00 | 2.00 | 0.38 | 1.25 | 36,000 | 6.30 | |

| WH82XHD | 3.075 | 1.25 | 0.75 | 3.75 | 1.13 | 2.38 | 0.38 | 1.50 | 57,000 | 8.50 | |

| WH124XHD | 4.063 | 1.63 | 1.00 | 4.88 | 1.50 | 3.00 | 0.50 | 2.00 | 122,000 | 14.60 | |

| WH106XHD | 6.050 | 1.75 | 1.00 | 4.88 | 1.50 | 3.00 | 0.50 | 2.00 | 122,000 | 11.80 | |

| WH132XHD | 6.050 | 1.75 | 1.00 | 6.75 | 2.75 | 4.66 | 0.63 | 2.00 | 122,000 | 15.30 | |

Add IBR or fully heat treated parts plus induction hardened barrels and rivets.

John King offer a unique range of welded steel chains dimensionally equivalent to M Series bush chains according to DIN8167. The chain offers all the benefits of the “offset” sidebar welded construction and can be offered as a direct replecement in existing conveyors and operate on same sprockets. This allows the user a unique opportunity to improve reliability and service life without major alteration.

Key Features:

- Direct replacement with Metric standard DIN 8167,

- Increased ultimate tensile strength of up to 65% as compared to standard M series chain,

- Welded bush for increased shock resistance,

- Best specification with all parts through hardened and surface induction hardening on pins and bushes,

- Crank link design as US standard ISO DP6972. A beneficial construction with maintenance advantages,

- Option to induction harden sliding surfaces,

- Grease lubrication can be included if required,

- Ease of maintenance with an option to remove one offset link not two as with straight sidebar chain.

| Chain Number | Pitch (P) (mm) |

Bushings | Over-All Pin (F1) (mm) |

Between Sidebars (L) (mm) |

Sidebars | Breaking Load (kN) |

Weight (kg/m) |

||

|---|---|---|---|---|---|---|---|---|---|

| Diameter (D5) (mm) |

Diameter (D6) (mm) |

Thickness (S) (mm) |

Height (H) (mm) |

||||||

| WHM160/100/IBR* | 100 | 25 | 18 | 72 | 37 | 7 | 50 | 270 | 9.5 |

| WHM160/125/IBR* | 125 | 25 | 18 | 72 | 37 | 7 | 50 | 270 | 8.7 |

| WHM160/160/IBR* | 160 | 25 | 18 | 72 | 37 | 7 | 50 | 270 | 8.0 |

| WHM224/160/IBR* | 160 | 30 | 21 | 84 | 42 | 8 | 60 | 375 | 12.8 |

| WHM224/200/IBR* | 200 | 30 | 21 | 84 | 42 | 8 | 60 | 375 | 11.6 |

| WHM224/250/IBR* | 250 | 30 | 21 | 84 | 42 | 8 | 60 | 375 | 10.8 |

| WHM315/160/IBR* | 160 | 36 | 25 | 97 | 48 | 10 | 70 | 520 | 17.8 |

| WHM315/200/IBR* | 200 | 36 | 25 | 97 | 48 | 10 | 70 | 520 | 16.4 |

| WHM450/200/IBR* | 200 | 42 | 30 | 116 | 56 | 12 | 80 | 700 | 23.8 |

| WHM450/250/IBR* | 250 | 42 | 30 | 116 | 56 | 12 | 80 | 700 | 22.1 |

| WHM630/200/IBR* | 200 | 50 | 36 | 136 | 66 | 14 | 100 | 900 | 38.9 |

| WHM630/250/IBR* | 250 | 50 | 36 | 136 | 66 | 14 | 100 | 900 | 34.2 |

| WHM630/315/IBR* | 315 | 50 | 36 | 136 | 66 | 14 | 100 | 900 | 31.7 |

* IBR represents uprated specification with fully heat-treated components together with induction hardened barrel (bush) and pin.

K1 attachments & A1 attachments (If one side)

| Chain Number | A (inches) | B (inches) | C (inches) | J (inches) | D (inches) | Z (inches) | Y (inches) | Average Weight (lbs/ft) |

|---|---|---|---|---|---|---|---|---|

| WH78 | 2.00 | 2.50 | 1.25 | 0.25 | 0.38 | 1.25 | 0.88 | 5.50 |

| WH78XHD | 2.00 | 2.50 | 1.25 | 0.25 | 0.38 | 1.25 | 0.88 | 7.50 |

| WH82 | 2.38 | 3.00 | 1.75 | 0.25 | 0.38 | 1.50 | 0.88 | 7.20 |

| WH82XHD | 2.38 | 3.00 | 1.75 | 0.38 | 0.38 | 1.50 | 1.13 | 11.00 |

| WH124 | 2.63 | 3.25 | 1.75 | 0.38 | 0.38 | 2.00 | 1.13 | 11.70 |

| WH124XHD | 2.63 | 3.38 | 1.75 | 0.50 | 0.50 | 2.00 | 1.50 | 18.50 |

| WH111 | 3.13 | 3.75 | 1.75 | 0.38 | 0.38 | 2.13 | 1.25 | 22.40 |

| WH132 | 3.75 | 4.63 | 2.00 | 0.50 | 0.50 | 3.00 | 1.50 | 18.90 |

| WH132XHD | 3.75 | 4.63 | 2.00 | 0.50 | 0.50 | 3.00 | 1.50 | 19.80 |