Contents

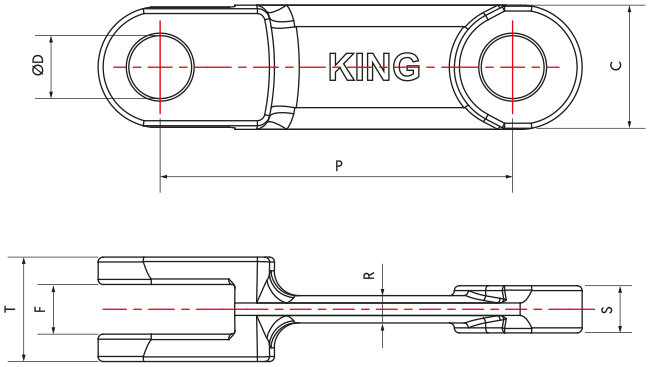

This series represents the leading product within the John King programme. Forged fork link chain has proven to be one of the most reliable conveying mediums offering a combination of versality, strength and abrasion resistance. These chains, originally of european origin, are now established worldwide. With a wide variety of materials, heat treatments and flight formats the chain is proven in both drag and enmasse handling.

| Chain Number | P (mm) | T (mm) | C (mm) | S (mm) | F (mm) | R (mm) | Bolt Hole Diameter (mm) | TN (kN) | CN (kN) | CD (kN) | Weight (kg/m) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| JKF 10160 | 101.6 | 24 | 36 | 9 | 10 | 6 | 14 | 110 | 120 | 210 | 3.50 |

| JKF 10160R | 101.6 | 30 | 36 | 13 | 14 | 9 | 14 | 180 | 195 | 330 | 4.80 |

| JKF 12514 | 125 | 30 | 36 | 13 | 14 | 10 | 16 | 163 | 175 | 290 | 4.40 |

| JKF 14214 | 142 | 32 | 41 | 14 | 15 | 9 | 18 | 180 | 195 | 330 | 4.90 |

| JKF 14218 | 142 | 42 | 50 | 19 | 20 | 12 | 25 | 290 | 320 | 550 | 9.40 |

| JKF 14222 | 142 | 54 | 50 | 25 | 27 | 16 | 25 | 370 | 400 | 655 | 12.20 |

| JKF 14226 | 142 | 62 | 50 | 28 | 30 | 16 | 25 | 440 | 470 | 790 | 13.60 |

| JKF 16018 | 160 | 46 | 46 | 22 | 24 | 15 | 22 | 320 | 342 | 560 | 9.30 |

| JKF 16025 | 160 | 50 | 53 | 23 | 25 | 13 | 25 | 370 | 400 | 655 | 10.80 |

| JKF 20025 | 200 | 60 | 50 | 25 | 27 | 18 | 25 | 380 | 410 | 670 | 11.30 |

| JKF 20028 | 200 | 66 | 60 | 30 | 32 | 20 | 30 | 500 | 540 | 900 | 16.70 |

| JKF 21640 | 216 | 64 | 72 | 26 | 28 | 20 | 35 | 585 | 630 | 1035 | 20.10 |

| JKF 22040 | 220 | 64 | 72 | 26 | 28 | 20 | 35 | 585 | 630 | 1035 | 20.30 |

| JKF 22050 | 220 | 58 | 75 | 28 | 30 | 25 | 32 | 710 | 760 | 1260 | 19.10 |

| JKF 22060 | 220 | 71 | 75 | 31 | 33 | 21 | 35 | 735 | 790 | 1300 | 22.90 |

| JKF 25040 | 250 | 70 | 75 | 32 | 34 | 18 | 32 | 735 | 860 | 1430 | 18.80 |

| JKF 26035 | 260 | 65 | 75 | 31 | 33 | 20 | 32 | 840 | 900 | 1480 | 19.80 |

| JKF 26040 | 260 | 70 | 75 | 31 | 33 | 20 | 32 | 840 | 900 | 1480 | 21.00 |

| JKF 26045 | 260 | 78 | 75 | 35 | 37 | 20 | 32 | 930 | 1000 | 1650 | 21.80 |

* TN – Manganese Chrome Alloy Steel (20MnCr5) Case hardened

CN – Chrome Nickel Alloy Steel (18NiCoMo5) Case Hardened

CD – Chrome Molly Alloy Steel (42CrMo4) Hardened & Tempered

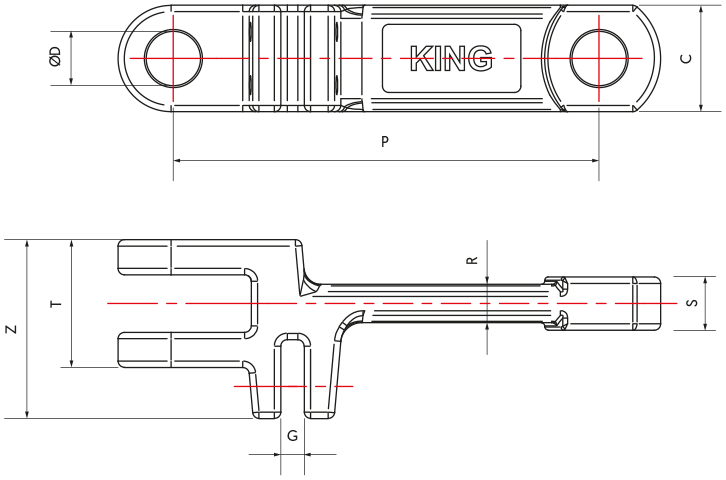

For double strand assemblies John King have a range of links following the standard format but with a forged “double clevis” into which a scraper can be mounted. The flight blade can be retained by either a U bolt or standard fasteners. The chain allows for some built in clearance between strands which obviates any potential problems that may be associated with mismatch. Double strand allows for improved discharge particularly relevant in conveying sticky materials.

| Chain | P (mm) | T (mm) | C (mm) | S (mm) | Z (mm) | G (mm) | Bolt Hole Diameter (mm) | TN (kN) | CN (kN) | CD (kN) | Weight (kg/m) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| JKF 142182 | 142 | 42 | 50 | 19 | 70 | 13 | 25 | 290 | 320 | 550 | 11.80 |

| JKF 142262 | 142 | 62 | 50 | 28 | 87 | 13 | 25 | 440 | 470 | 790 | 16.70 |

| JKF 160252 | 160 | 50 | 53 | 23 | 82 | 13 | 25 | 370 | 400 | 655 | 13.60 |

| JKF 175402 | 175 | 72 | 60 | 30 | 95 | 16 | 30 | 540 | 580 | 955 | 20.30 |

| JKF 200252 | 200 | 60 | 50 | 25 | 81 | 12 | 25 | 380 | 410 | 670 | 13.00 |

| JKF 200402 | 200 | 70 | 60 | 30 | 95 | 13 | 30 | 540 | 580 | 955 | 19.30 |

| JKF 250252 | 250 | 60 | 50 | 25 | 81 | 12 | 25 | 380 | 410 | 670 | 12.00 |

| JKF 250402 | 250 | 70 | 60 | 30 | 95 | 13 | 30 | 540 | 580 | 955 | 17.70 |

| JKF 250602 | 250 | 100 | 70 | 45 | 140 | 21 | 35 | 975 | 1050 | 1720 | 35.20 |

Attachment hole positions and sizes can be varied to meet customer requirements.

* TN – Manganese Chrome Alloy Steel (20MnCr5) Case hardened

CN – Chrome Nickel Alloy Steel (18NiCoMo5) Case Hardened

CD – Chrome Molly Alloy Steel (42CrMo4) Hardened & Tempered

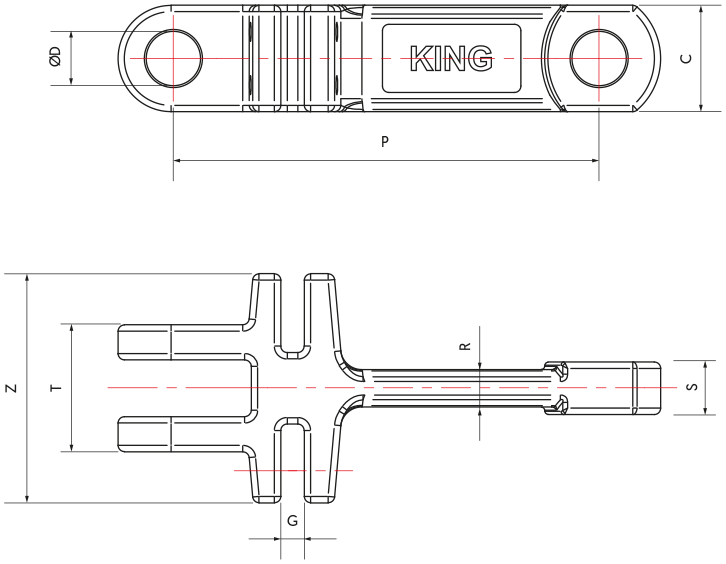

Where extra wide flights are required the John King triple link is available allowing, in conjunction with the double on perimeters, three chain strands up to 3100 mm overall. In addition the “Double slot” allows for a versatile means or flight retention for both steel & plastic options. Retention can be either U clips or standard fasteners.

| Chain | P (mm) | T (mm) | C (mm) | S (mm) | Z (mm) | G (mm) | Bolt Hole Diameter (mm) | TN (kN) | CN (kN) | CD (kN) | Weight (kg/m) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| JKF 142183 | 142 | 42 | 50 | 19 | 92 | 13 | 25 | 290 | 320 | 550 | 14.20 |

| JKF 142263 | 142 | 62 | 50 | 28 | 112.3 | 13 | 25 | 440 | 470 | 790 | 19.80 |

Attachment hole positions and sizes can be varied to meet customer requirements.

* TN – Manganese Chrome Alloy Steel (20MnCr5) Case hardened

CN – Chrome Nickel Alloy Steel (18NiCoMo5) Case Hardened

CD – Chrome Molly Alloy Steel (42CrMo4) Hardened & Tempered

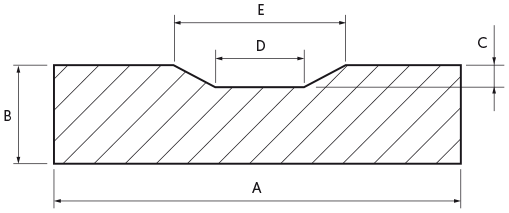

The standard recommendation for forged chain wear rail is manganese steel, an austenitic structure, offering unique work hardening properties. In its rolled condition it offers a hardness value of 200-220 Bnh increasing up to 600 Bnh if the optimum conditions prevail.

| Reference | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | Weight (kg/m) |

|---|---|---|---|---|---|---|

| 49/25X10 | 25.0 | 10.0 | 2.0 | 5.0 | 12.0 | 1.83 |

| 49/40X10 | 40.0 | 10.0 | 2.0 | 5.0 | 12.0 | 3.01 |

| 49/50X10 | 50.0 | 10.0 | 2.0 | 5.0 | 12.0 | 3.82 |

| 49/60X10 | 60.0 | 10.0 | 2.5 | 6.0 | 16.0 | 4.45 |

| 49/60X12 | 60.0 | 12.0 | 2.5 | 6.0 | 16.0 | 5.50 |

| 49/60X20 | 60.0 | 20.0 | 3.0 | 6.0 | 16.0 | 9.15 |