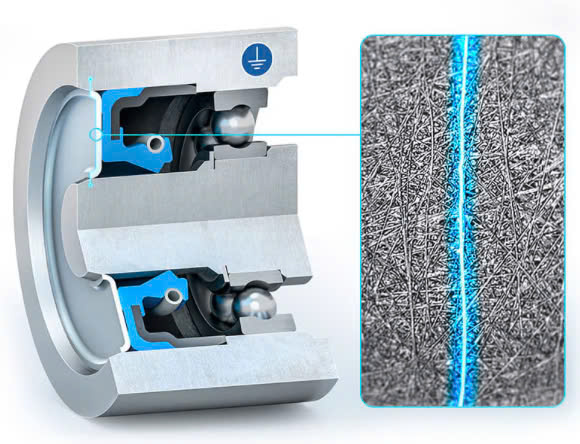

eCON – Electrically Conductive Nonwoven Component for Safe Grounding

Use eCON to Avoid Bearing Damage in Electric Motors

Damaged bearings are a common problem in powerful electric motors. Due to bearing currents and the accompanying electrical erosion, these damages lead to increased noise, vibrations and, in extreme cases, failure of the rolling bearings. eCON, the electrically conductive nonwoven component from Freudenberg, diverts these currents away from the bearing, thus helping to extend its service life.

Freudenberg offers three variants of its grounding system: exclusively as a grounding system (eCON pure), in combination with a friction-optimized Low-Friction Simmerring® (eCON LFS) or combined with a gas-lubricated mechanical seal (eCON LEVITEX).