Pneumatic Air Cylinder Seals

One Part Replaces Three Components

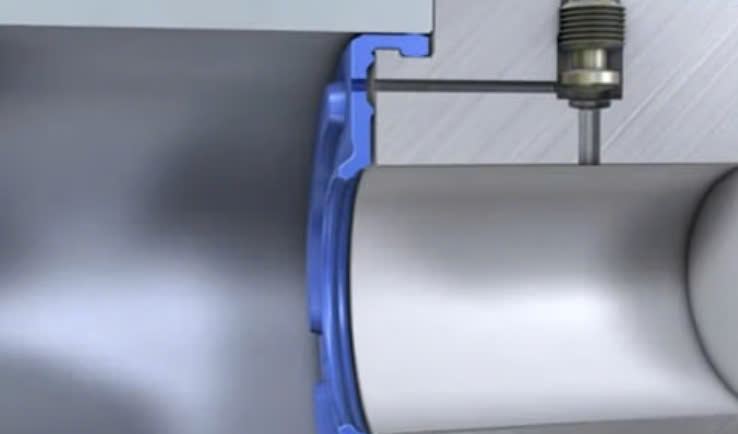

The damping seal from Freudenberg Sealing Technologies combines the functions of what would normally be three components into a single part. This not only simplifies processes for the manufacture of pneumatic cylinders, but it also simplifies purchasing, storage and logistics as well. In addition, damping seals offer outstanding damping characteristics thanks to its specific design and highly stressable materials.

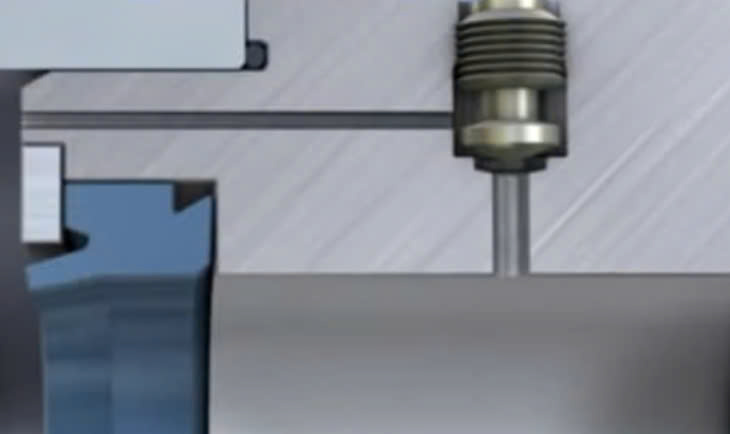

In pneumatic cylinders, the kinetic energy of the moving masses is reduced shortly before they reach the stop position, generally due to the compression of air volume and a defined throttling of the exhaust air. In today’s standard designs, these distinct functions are performed by several components: the actual damping seal, the O-ring for static sealing, and an additional elastomer stop washer, for cases when the piston strikes the cover with a residual speed despite the pneumatic damping. The installation groove for the damping seal is either machined or a morticed retaining ring is required.